Myth #5: Container scheduling and decking should be done by the TOS

Myth #5: Container scheduling and decking should be done by the TOS

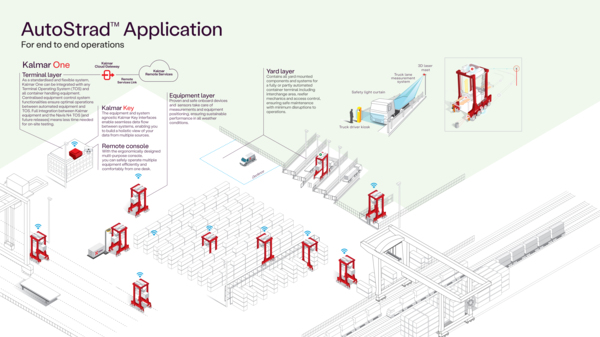

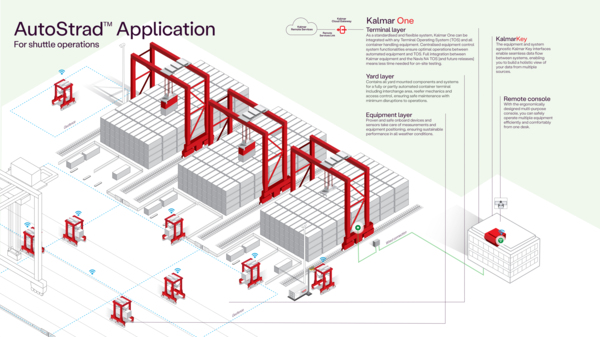

Kalmar AutoStrad™

Automated straddle carriers designed for terminal and intermodal operations

AutoStrad™

Le Kalmar AutoStrad™ constitue la solution idéale pour les terminaux moyens à grands pour lesquels flexibilité des équipements et frais de main d'œuvre réduits sont essentiels.

DOWNLOADS

Technical information

| Informations techniques | AutoStrad™ |

|---|---|

|

Hauteur de gerbage (9'6)

|

3 or 4 |

|

Capacité de levage (kg)

|

40/50/60 tons |

|

Moteur

|

~11 l or ~5 l or none |

|

Power unit

|

Diesel-electric/Diesel-Hybrid/Battery |

|

Hoisting system

|

Electric winch rope |

| Informations techniques | AutoStrad™ |

|---|---|

|

Hauteur de gerbage (9'6)

|

3 or 4 |

|

Moteur

|

~11 l or ~5 l or none |

|

Power unit

|

Diesel-electric/Diesel-Hybrid/Battery |

|

Hoisting system

|

Electric winch rope |

Simplicité, flexibilité et économie - le tout avec un seul engin

Une seule pièce étant nécessaire pour l'automatisation de vos opérations à quai et à terre et pour le gerbage, réaliser un terminal automatisé peut être simple, peu risqué et réalisable en un temps relativement court.

Automatiser les parcs existants

Pratiquement tous les modèles de cavaliers straddle Kalmar peuvent être automatisés à peu de frais. Nous pouvons assurer la préservation de vos cavaliers straddle pour l'avenir au moment de la fabrication en les configurant pour un fonctionnement manuel ou totalement automatisé, vous laissant la liberté d'avancer vers l'automatisation à votre propre rythme.

You need to accept targeting cookies before you can view the YouTube content. Those cookies may be used to show you relevant content and adverts. Click the button “Cookie Settings” to manage your preference.

Produits associés

Services offering

You need to accept targeting cookies before you can view the YouTube content. Those cookies may be used to show you relevant content and adverts. Click the button “Cookie Settings” to manage your preference.